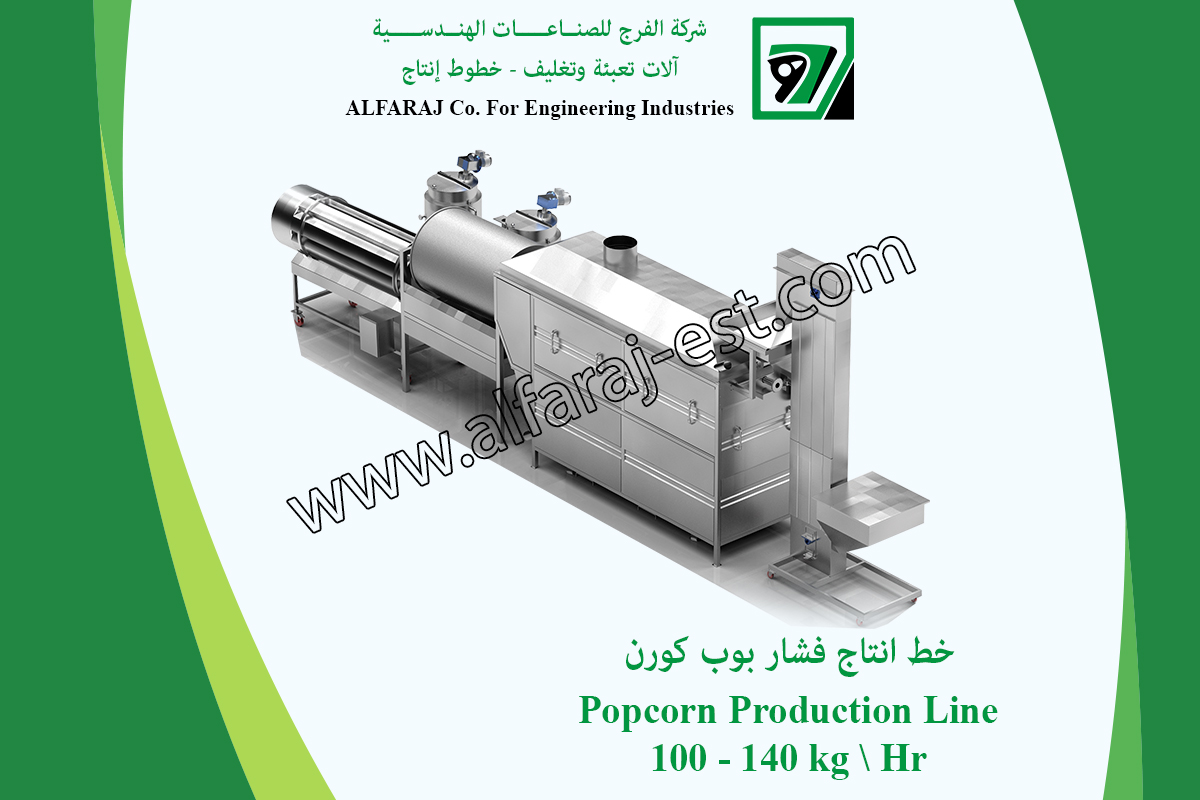

Popcorn Production Line

Popcorn Production Line 100 - 140 kg \ Hr

Popcorn Production Line Manufactured by ALFARAJ For Engineering Industries.

Production line (popcorn) productivity (American model 100 /140 kg / hr)

Line specification

The space required for the operation of the line is 10 × 2.5 m.

The line consists of the following components:

The flow of a lift: the raw materials (maize) are transported to the popcorn explosive device.

Detonator detonation machine: the process of blowing up and converting corn grain into popcorn.

cylinder (DRM) in a diameter of 70 cm and 1 cm in length to filter the popcorn from the suspended material (immature grains).

cylinder (DRM) in diameter of 70 cm and 2.5 m long to vaccinate the product with the required flavour.

A 175-litre flavor mixer with a flavor to pump the flavor on the product.

All surfaces that touch the product are from the 304 – food chrome.

Production capacity: 100 kg / hour

Raw Material feeder vebrator

Made of chromium (304) Full flow control with variable velocity resistance

Machine blowing the popcorn beads

American System (Popping machine):

The author of the reservoir to pass the corn coming from the conveyor.

Equipped with a vibrator to facilitate the movement of the corn.

All parts touching materials are made of stainless steel/304.

The heating line is based on a gas-operated lighter system for better performance and lower cost.

The heating system operates with a lighter (Diesel/oil burner) to regulate temperature – an Italian industry.

The heating system with a special thermal medium suitable for blowing corn is excellent.

Line Productivity (100-140 kg/hour) and works with a very special type of American system

The Sieve machine

Made of full-chrome food, his job is to isolate an immature granule with an engine Flavor Unit

Made of chromium food mixing materials with flavored and spicy oil length 3.00 m diameter cm 60A horses with an inverter. 1 engine

Oil and Flavor Mixer

Composed of: (oil tank and bait number 1 + pump bait + drem flipping bait).

The reservoir and the derm flipping are made of stainless steel (304) and equipped with a angular mixer engine to perform better for mixing process.

The tank is fitted with a double jacket for electrically heated.

Production of natural popcorn

The Popcorn Frying Process

Popcorn frying is a complex process that requires precise control of temperature and humidity. To create the perfect fried popcorn, kernels are heated in a specialized machine until they pop, and then immersed in hot oil for a specific amount of time. The moisture in the popcorn is evaporated, leaving behind a crispy, light snack.

ipment Needed in Popcorn Frying

Popcorn Machine

A specialized popcorn machine is used to heat the kernels to the perfect temperature and humidity for frying.

Fryer

A fryer is used to heat the oil and fry the popcorn.

Oil Filter

An oil filter is used to ensure the quality of the oil by removing impurities and particles.

Safety Measures in Popcorn Frying Factories

Protective Clothing

Workers operating the fryer must wear protective clothing, including gloves and aprons.

Fire Protection

Popcorn factories must have adequate fire protection measures in place, including sprinklers and fire extinguishers.

Proper Ventilation

Popcorn frying produces fumes that can be hazardous, so proper ventilation is necessary to protect employees.

Types of Popcorn Frying Oils

Corn Oil

The most commonly used oil in popcorn frying because it produces a light and crispy snack.

Coconut Oil

Produces a rich and buttery flavor, and is often used in movie theaters.

Palm Oil

Has a high smoke point and is used in commercial frying due to its long shelf life.

Quality Control of Fried Popcorn

Texture

Fried popcorn must have the right texture and crunch to be enjoyed. Quality control measures are in place to ensure this is achieved.

Appearance

The popcorn must have an appealing appearance and color, free from any black or burned spots.

Flavor

The popcorn must have a pleasant aroma and taste, with no undesirable flavors or aromas.

Packaging of Fried Popcorn

Fried popcorn is packaged in a variety of materials, including plastic bags and cardboard boxes. The packaging must protect the popcorn from moisture and air, which can change its texture and flavor. It must also be eye-catching and easily recognizable to consumers.

Marketing Fried Popcorn Products

Choose a memorable brand name and package design that sets your product apart. Highlight the nutritional value and unique flavor of your fried popcorn, and promote it in stores, online, and at events.

Organize fun and engaging experiences for your customers, such as cooking classes and social media contests. Partner with other businesses to offer discounts, giveaways, and promotions.

QUESTIONS?

Contact us and ask your question. Find your request with us

QUESTIONS?

Contact us and ask your question. Find your request with us